Revolutionizing EV Batteries: Advances in Solid-State and Lithium-Ion Technologies

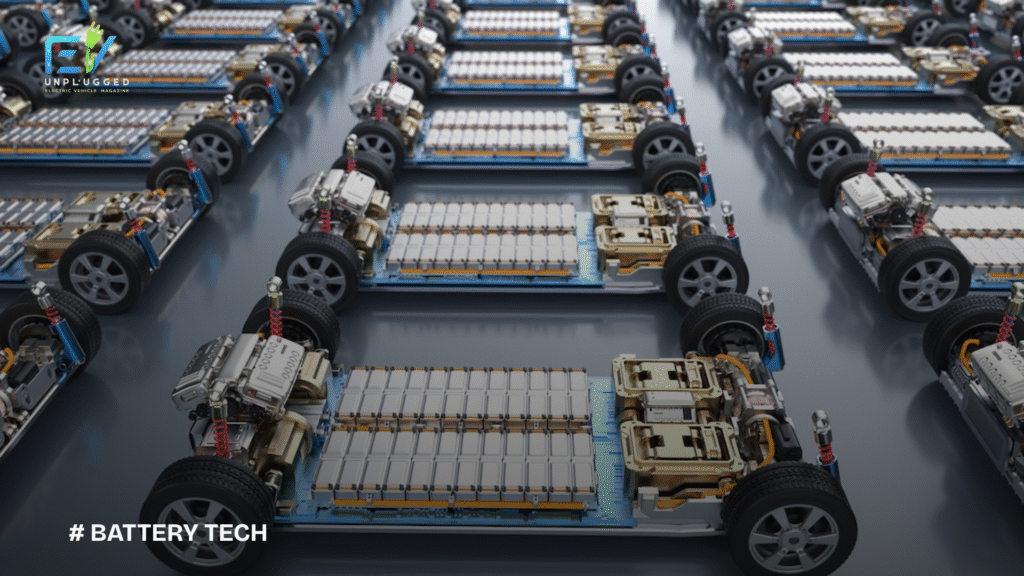

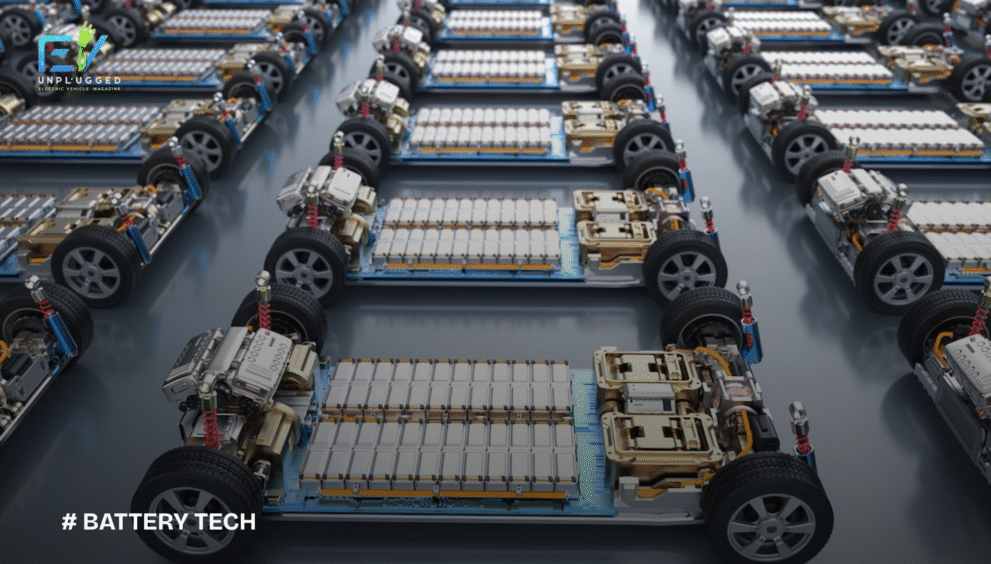

Electric vehicles (EVs) have emerged as the future of sustainable transportation, playing a pivotal role in reducing carbon emissions and combating climate change. At the heart of this revolution lies a critical component — the battery. Battery technology determines an EV’s range, safety, charging speed, and overall cost, directly impacting consumer adoption and industry growth.

Currently, lithium-ion batteries dominate the EV landscape. However, limitations in energy density, charging speed, and safety have pushed researchers and manufacturers to explore new solutions, such as solid-state batteries. These technological advances are reshaping the electric mobility ecosystem worldwide, including in India, where ambitious policies aim to accelerate EV adoption.

This article delves into the latest advancements in solid-state and lithium-ion battery technologies, highlighting their implications for the EV sector and the broader clean mobility movement.

The Dominance and Limitations of Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries have powered the rise of electric mobility over the past decade. According to the International Energy Agency (IEA), over 95% of electric vehicles on the road today use lithium-ion battery packs due to their favorable energy density, cost-effectiveness, and reliability.

Key advantages of lithium-ion batteries:

- High Energy Density: Li-ion cells store more energy per unit weight and volume compared to earlier chemistries, allowing EVs to travel between 300 to 500 kilometers per charge in most models.

- Cost Decline: Battery pack prices have dramatically fallen from over $1,200 per kWh in 2010 to approximately $130 per kWh in 2023 (BloombergNEF), making EVs more affordable.

- Established Supply Chains: A mature ecosystem of battery manufacturing and recycling is evolving globally.

However, several challenges remain:

- Limited Range: Although improving, current lithium-ion batteries still constrain vehicle range, impacting consumer confidence (range anxiety).

- Charging Times: Fast charging is often limited by battery chemistry and thermal management, with prolonged charging times discouraging potential buyers.

- Safety Risks: Li-ion batteries use flammable liquid electrolytes, which pose fire hazards in case of damage or thermal runaway.

- Material Supply Constraints: Lithium, cobalt, and nickel mining pose ethical, environmental, and supply chain challenges, threatening long-term sustainability and cost stability.

Given these challenges, the EV industry is actively pursuing innovations to overcome lithium-ion battery limitations.

Solid-State Batteries: The Next Generation Breakthrough

Solid-state batteries (SSBs) replace the liquid or gel electrolyte in conventional lithium-ion cells with a solid electrolyte, enabling significant improvements in energy storage and safety.

Advantages of solid-state battery technology include:

- Higher Energy Density: Solid electrolytes enable denser packing of lithium ions, potentially doubling or tripling energy density compared to traditional lithium-ion cells. This translates to EV ranges of 600 to 700+ kilometers per charge.

- Enhanced Safety: Solid electrolytes are non-flammable, drastically reducing risks of battery fires or explosions, even under severe mechanical or thermal stress.

- Faster Charging Capability: SSBs can support higher charging currents without damaging the cell, allowing rapid recharge times that are safer and more convenient.

- Longer Lifespan: Reduced degradation from dendrite formation leads to longer battery life and more charge-discharge cycles.

Global and Indian Developments in Solid-State Batteries

Global players like QuantumScape (USA), Toyota (Japan), and Solid Power (USA) are at the forefront of commercializing solid-state battery technology, aiming for production-scale manufacturing by the late 2020s.

In India, startups such as Log 9 Materials and Tonbo Imaging are advancing research into solid-state and other next-generation batteries to support the country’s EV push. The Indian government’s production-linked incentives (PLI) scheme for battery manufacturing encourages indigenous innovation and reduces dependency on imports.

Market research firm MarketsandMarkets projects the solid-state battery market to grow at a compound annual growth rate (CAGR) of over 60% and reach USD 6.6 billion by 2028, underscoring the technology’s disruptive potential.

Innovations in Lithium-Ion Chemistry and Manufacturing

While solid-state batteries hold promise for the future, lithium-ion battery technology continues to evolve through chemical and manufacturing improvements:

- Nickel-Rich Cathodes (NMC 811): Increasing nickel content reduces reliance on expensive cobalt, enhances energy density, and lowers costs.

- Silicon Anodes: Silicon can store ten times more lithium ions than graphite anodes, boosting battery capacity and range. However, silicon’s expansion during charging requires advanced nano-engineering to ensure stability.

- Cobalt-Free Batteries: Developing cobalt-free cathodes improves ethical sourcing and cost-efficiency.

- Advanced Electrolytes: New electrolyte formulations enable faster charging and improved battery life.

- Battery Cell Design: Tesla’s new “4680” cells employ tabless architecture, enhancing thermal management and power output.

Indian battery manufacturers like Exide Industries and automakers like Tata Motors are collaborating to develop lithium-ion cells tailored for Indian conditions, enhancing durability in hot climates and affordability for mass-market EVs.

Impact on EV Adoption and Industry Growth

Battery innovation is a key enabler for the electric vehicle revolution:

- Addressing Range Anxiety: Increased energy density and better battery management extend driving range, reducing consumer hesitation.

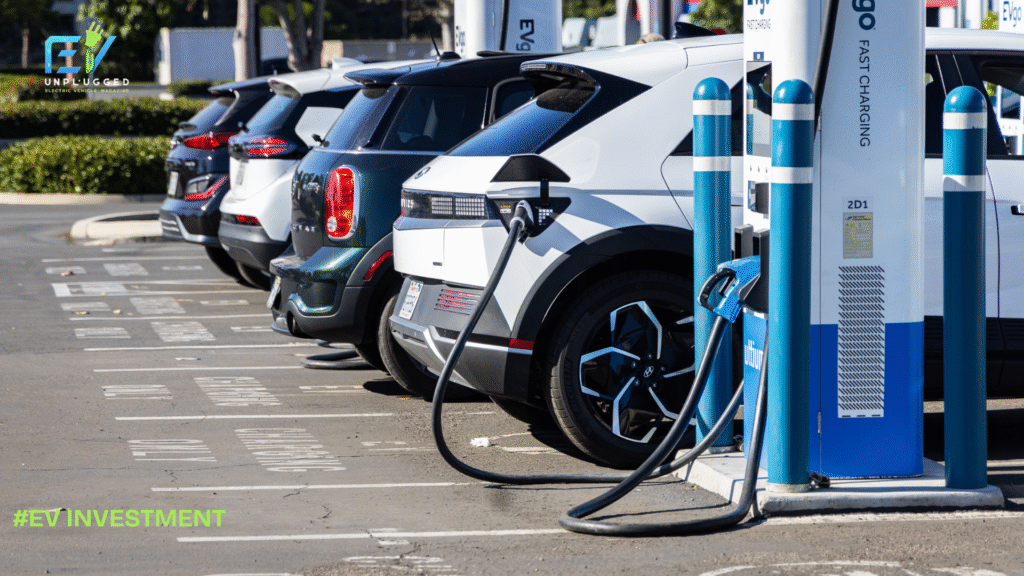

- Faster, Convenient Charging: Advancements in fast-charging batteries and supporting infrastructure enhance user experience.

- Improved Safety: Safer battery chemistries increase consumer trust and regulatory acceptance.

- Lower Total Cost of Ownership: Declining battery prices and longer lifespans make EVs economically competitive with internal combustion engine (ICE) vehicles.

Government initiatives such as India’s FAME II (Faster Adoption and Manufacturing of Hybrid and Electric Vehicles) scheme and the PLI program for advanced battery manufacturing provide financial incentives and policy support to accelerate domestic production and adoption.

BloombergNEF estimates that by 2030, EVs will make up over 60% of new passenger vehicle sales globally, largely driven by battery technology breakthroughs.

Challenges and Future Outlook

Despite rapid progress, several challenges remain:

- Manufacturing Scale: Solid-state battery production at commercial scale involves high costs and technical complexity that need to be overcome.

- Raw Material Supply: Sustainable sourcing of lithium, nickel, and other materials is essential to avoid environmental damage and price volatility.

- Battery Recycling: Developing efficient recycling and second-life applications is crucial for resource conservation.

- Infrastructure Development: Fast-charging networks and battery swapping solutions must evolve alongside battery technology.

Nevertheless, ongoing collaborations among automakers, startups, research institutions, and governments promise a bright future for battery innovation.

Conclusion

Battery technology remains the cornerstone of electric vehicle development and adoption. While lithium-ion batteries have propelled EVs to mainstream success, solid-state batteries and next-generation lithium-ion chemistries are poised to revolutionize the industry with longer range, faster charging, enhanced safety, and affordability.

For India, advancing battery innovation through domestic manufacturing and research aligns with national clean energy goals and economic growth. As battery technologies mature, they will unlock new possibilities for sustainable transportation, enabling a cleaner, greener future worldwide.

English

English