What India’s New Battery Waste Rules Mean for EV OEMs and Battery Manufacturers

ndia’s electric vehicle (EV) revolution is accelerating rapidly. With government incentives, rising fuel costs, and growing climate awareness, EV adoption across two-wheelers, cars, and commercial vehicles is scaling new heights. According to NITI Aayog, India aims for EVs to constitute 30% of new vehicle sales by 2030.

But this surge in EV adoption brings with it a lesser-discussed challenge: battery waste.

EV batteries, primarily lithium-ion-based, have a limited lifecycle and contain hazardous elements. Without proper end-of-life management, these batteries pose environmental and safety risks. In response, the Indian government introduced a comprehensive legal framework: the Battery Waste Management Rules, 2022, notified by the Ministry of Environment, Forest and Climate Change (MoEFCC).

These rules mark a significant shift in how India manages battery waste, placing new responsibilities on manufacturers and unlocking new opportunities in battery recycling.

Key Highlights of the Battery Waste Management Rules, 2022

The Battery Waste Management Rules, 2022 aim to ensure environmentally sound management of waste batteries, especially with EV adoption on the rise. Here are the key takeaways:

1. Extended Producer Responsibility (EPR)

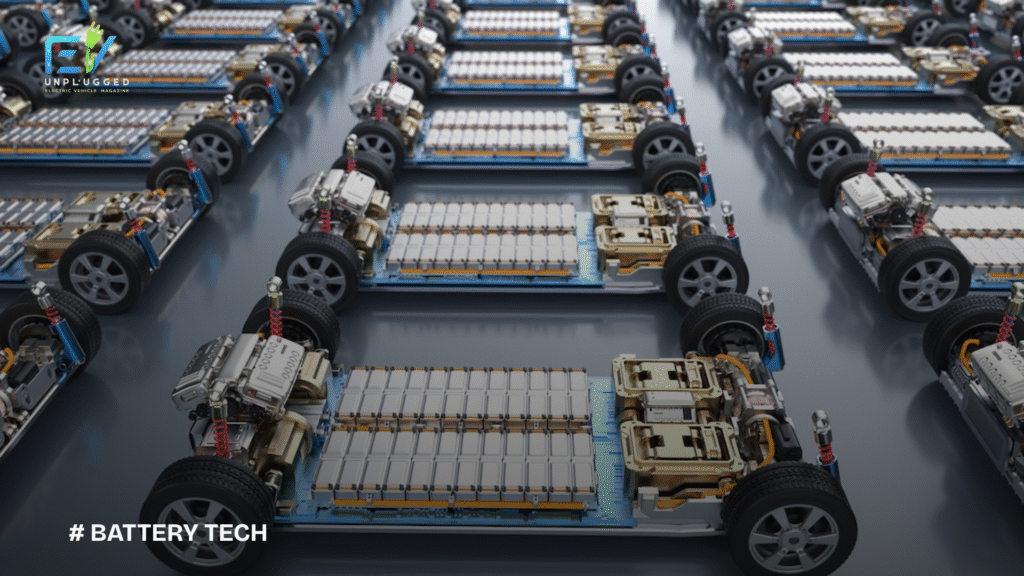

At the heart of the new rules lies Extended Producer Responsibility (EPR). Under this framework, EV OEMs (Original Equipment Manufacturers), battery manufacturers, importers, and re-conditioners are responsible for the collection, recycling, and reuse of used batteries.

Producers must ensure that used batteries are returned either to themselves or to registered recyclers/refurbishers.

2. Collection Targets

Producers are obligated to meet specific annual collection targets for used batteries, expressed as a percentage of the batteries they sell.

For instance:

- 2023–24: 70% collection

- 2024–25: 80%

- 2025–26 and onward: 90%

This ensures a steady stream of batteries entering the circular economy.

3. Battery Registration and Portal Integration

All battery manufacturers and EV OEMs must register on a centralized portal created by the Central Pollution Control Board (CPCB). This portal tracks battery sales, collection, and recycling data, enabling greater transparency and accountability.

Each battery must be traceable with unique identifiers, improving lifecycle tracking and ensuring that recycling obligations are met.

4. Authorized Recycling Channels

Only registered recyclers and refurbishers are authorized to handle end-of-life batteries. Informal sector recycling, which often leads to pollution and poor recovery, is being systematically phased out.

EV OEMs must either partner with authorized recyclers or establish in-house facilities that meet compliance standards.

5. Penalties for Non-Compliance

Failure to comply with EPR targets or other provisions can result in environmental compensation charges. These penalties will be proportional to the extent of default and calculated by the CPCB.

Additionally, non-compliant entities may lose their licenses or be blacklisted from manufacturing and importing batteries in India.

Official Notification: MoEFCC Battery Waste Rules 2022 PDF

What This Means for EV OEMs

1. Operational Impact

The new rules fundamentally alter how EV OEMs handle their battery supply chains. From procurement to post-sale, companies must:

- Maintain battery traceability records.

- Fulfill collection and recycling quotas.

- Integrate recycling partnerships into after-sales service models.

OEMs will now need a dedicated EPR compliance team or outsource this to registered PROs (Producer Responsibility Organizations).

2. Financial Implications

Compliance with the new rules may increase costs, at least in the short term. Companies must invest in:

- Technology platforms for battery tracking.

- Reverse logistics for battery collection.

- Contracts with authorized recyclers/refurbishers.

However, these costs are expected to reduce over time as economies of scale and recycling technologies mature.

3. In-House Recycling Facilities or Strategic Tie-Ups

Leading OEMs may choose to set up in-house battery recycling units, especially if their volumes justify the investment. Others will opt for tie-ups with startups or existing recycling companies.

These partnerships will be crucial not only for compliance but also to secure valuable materials like cobalt, lithium, and nickel, which are otherwise expensive and largely imported.

4. Data Reporting and Transparency

EV OEMs must ensure real-time reporting of battery movement and end-of-life recycling through the CPCB portal. This will require tighter integration between sales, service, logistics, and compliance functions.

Opportunities in Battery Recycling

While compliance is a new responsibility, it also unlocks massive business potential.

1. The Rise of the Circular Battery Economy

As battery volumes increase, recycling becomes both a regulatory requirement and a revenue opportunity. High-value metals recovered from end-of-life batteries can be re-used in new cells, reducing raw material dependency and production costs.

This creates a circular loop, turning battery recycling from a liability into an asset.

2. Emerging Recycling Players in India

India’s battery recycling ecosystem is rapidly maturing. Notable players include:

- Attero Recycling: One of India’s largest e-waste and battery recyclers, with proprietary lithium-ion battery recycling technology.

- Lohum: Focuses on battery reuse and recycling, offering full-stack battery lifecycle management.

- Gravita India: Traditionally a lead-acid recycler, now expanding into lithium-ion recycling.

These companies are increasingly partnering with OEMs and fleet operators to ensure safe and profitable battery disposal.

Global Comparison: India vs. the World

India’s Battery Waste Rules align with global best practices but also differ in emphasis.

European Union (EU):

The EU’s Battery Regulation (2023) goes a step further by:

- Mandating a battery passport with embedded data.

- Requiring minimum recycled content in new batteries.

- Enforcing stringent carbon footprint disclosures.

United States (USA):

Battery recycling regulations in the US are more fragmented, but California’s Battery Recycling Act and federal incentives under the Inflation Reduction Act are pushing for improved recycling infrastructure and producer accountability.

India’s focus, while still evolving, emphasizes EPR and closing the loop, but lacks some of the recycled content mandates and carbon traceability metrics seen in the EU.

Conclusion: From Compliance to Strategy

The Battery Waste Management Rules, 2022, signal a strategic inflection point for India’s EV ecosystem. While the initial response may be compliance-driven, the long-term winners will be those who embrace sustainability as a competitive edge.

By investing in:

- Battery traceability technology

- Innovative recycling partnerships

- In-house reuse and refurbishing capabilities

companies can not only meet regulations but also lead the next wave of green innovation in mobility.

Stay Ahead of EV Regulations

Battery waste compliance is just the beginning. More updates are expected as India pushes for net-zero emissions and localized battery supply chains.

Subscribe to our newsletter or follow us for more deep-dives into EV regulations, industry trends, and sustainability insights.

Let’s drive the future—responsibly.

English

English